Discover comprehensive tips for maintaining your back-up generator. Regular inspection and maintenance ensure your generator is always ready when you need it.

Performing Routine Inspections

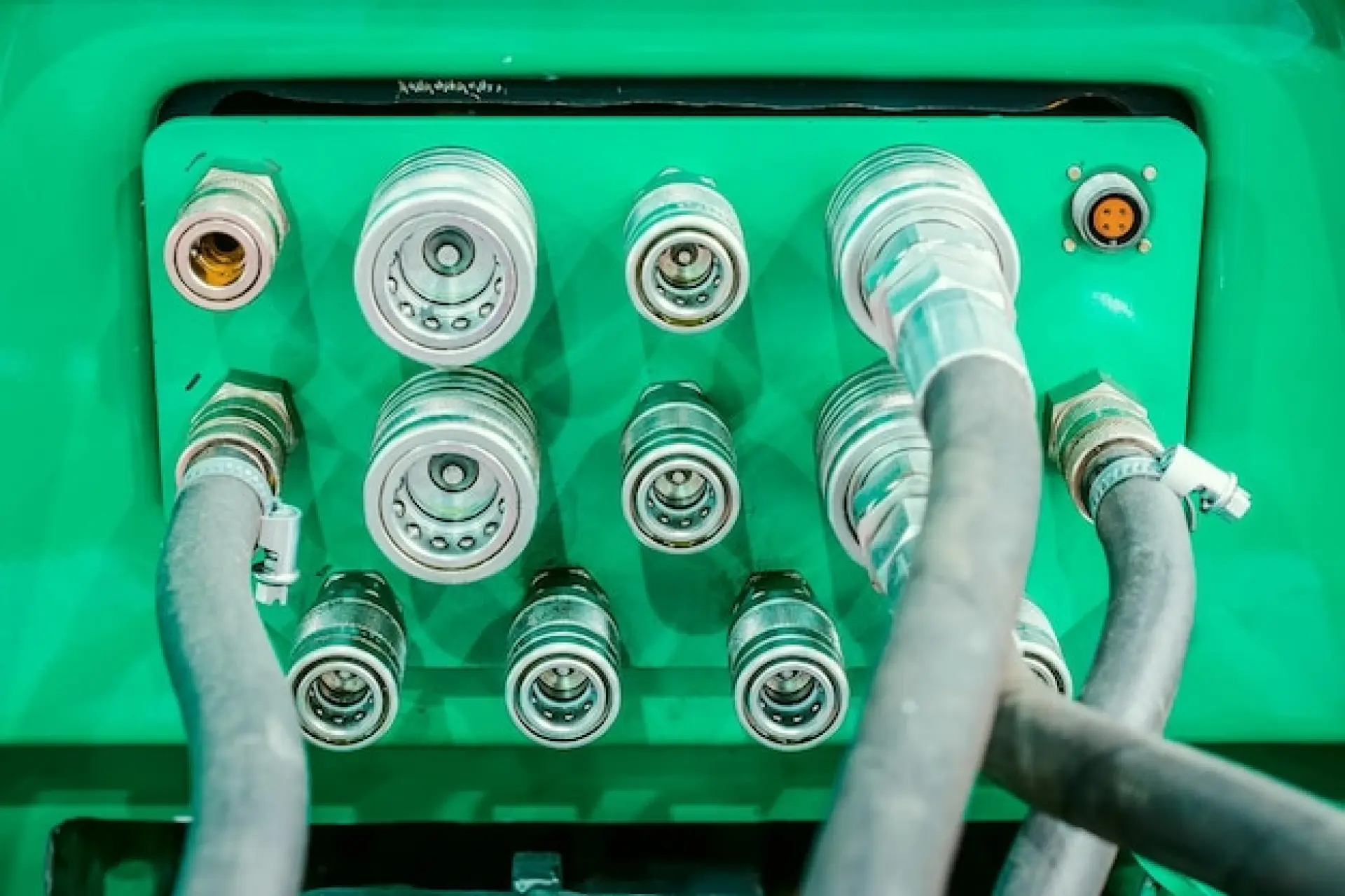

Regular inspections help keep your back-up generator in good working order. Check for visible signs of wear, such as loose connections, corrosion, or fluid leaks. Inspect the fuel system for blockages and ensure there are no signs of contamination. Examine hoses and belts for cracks or fraying, as these can lead to breakdowns. Ensure that vents and exhaust areas are clear of debris to prevent overheating.

Checking the generator’s control panel for error codes or warning lights can help identify potential issues early. Keeping a maintenance log allows you to track inspections and spot recurring problems. A thorough visual inspection at least once a month ensures that your generator remains ready for use when needed.

Checking and Changing Engine Oil

Oil is essential for keeping the generator’s engine running smoothly. Regularly check the oil level using the dipstick, ensuring it falls within the recommended range. If the oil appears dirty or too low, it should be changed to prevent engine damage.

Most manufacturers recommend an oil change after a set number of operating hours, typically every 50 to 200 hours, depending on the generator type. Always use the correct oil type as specified in the user manual.

Drain the old oil, replace the oil filter, and fill the engine with fresh oil. Running the generator for a few minutes after an oil change helps distribute the new oil evenly. Regular oil maintenance extends the generator’s lifespan and improves efficiency.

Ensuring that the oil remains clean and at the proper level is critical to preventing excessive engine wear. Dirty or degraded oil can cause friction, overheating, and increased component wear, leading to costly repairs or even complete engine failure.

When changing the oil, it is also essential to check for any metal shavings or unusual debris in the old oil, as this could indicate internal engine damage.

Additionally, always dispose of used oil properly by taking it to a recycling centre or an approved disposal site.

Keeping spare oil and filters on hand ensures that you can perform an oil change whenever necessary, especially during extended power outages. Proper oil management not only improves generator efficiency but also plays a crucial role in keeping it operational for years to come.

Inspecting and Replacing Air and Fuel Filters

Air and fuel filters prevent contaminants from entering the engine and fuel system. A clogged air filter can restrict airflow, leading to reduced performance and increased fuel consumption. Inspect the air filter regularly and clean or replace it as needed. Similarly, the fuel filter prevents debris from reaching the engine, ensuring smooth operation.

Over time, fuel filters can become blocked, leading to difficulty starting or reduced power output. Replacing the fuel filter according to the manufacturer’s recommendations helps prevent these issues. Always use the correct replacement filters for your generator model. Keeping both filters clean ensures that your generator runs efficiently and remains reliable during power outages.

Testing the Battery and Electrical Connections

A weak or faulty battery can prevent your generator from starting when needed. Regularly check the battery’s voltage and charge level using a multimeter. If the voltage is low, recharge or replace the battery as necessary. Inspect battery terminals for corrosion and clean them with a wire brush if needed.

Ensure all electrical connections are secure and free from damage. Loose or corroded connections can lead to electrical failures and unreliable performance. Testing the generator’s starting system periodically helps confirm that the battery and connections are functioning correctly. Proper battery maintenance ensures your generator is always ready to operate during an outage.

The battery is one of the most overlooked yet essential components of a generator. A fully charged and well-maintained battery ensures quick and reliable starts, which is particularly important during emergencies.

In addition to voltage checks, it is advisable to test the battery under load to ensure it can sustain power without significant drops in charge. If your generator has an automatic start feature, regularly testing it will confirm that the system is functioning properly.

Consider replacing the battery every three to five years, even if it appears to be working, as older batteries can fail unexpectedly. Keeping the battery terminals protected with anti-corrosion grease or spray can help extend their lifespan.

Additionally, storing a spare battery and keeping jumper cables handy can be useful in case of sudden battery failure. Investing time in battery maintenance can prevent unexpected failures and keep your generator operational when it matters most.

Running Your Generator Regularly to Prevent Issues

Running your generator regularly helps keep its components in good condition. A generator that sits idle for long periods may develop fuel degradation, battery discharge, or lubrication issues. Start the generator at least once a month and let it run under load for around 20 to 30 minutes. This helps circulate oil, charge the battery, and keep moving parts lubricated.

Running the generator also allows you to identify and address any issues before an emergency arises. If your generator runs on stored fuel, ensure it is fresh and use a fuel stabiliser to prevent degradation. Regular operation keeps your generator reliable and ready for use when needed.

Looking for reliable domestic electrician services in Surrey? Redwood Electrical Services is a team comprised of experienced and qualified electricians in the Woking, Guildford, and Cobham areas. Our team delivers friendly and professional electrical services, whether you're dealing with small issues like changing lights or larger projects like full house rewiring.